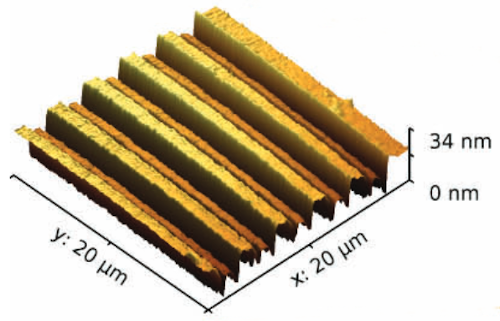

AFM Topography

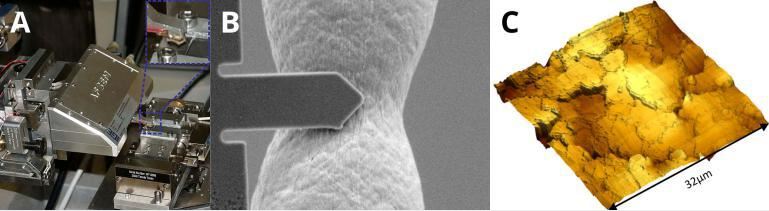

Quantitative height analysis with sub-nanometer resolution with a scanning electron microscopy (SEM) alone is not possible. An Atomic force microscopy (AFM) inside a SEM combines the strengths of both instruments. By using AFSEM® from GETec Microscopy and a tensile stage in-situ correlative analysis of a tensile stress samples was done. The tip-scanning AFM did not interfere with the use of the tensile stage.

AFSEM® and Deben 200N tensile stage installed in a Philips XL40 SEM (A). The SEM is used to localize the neck formation, quantify the degree of necking, and position the cantilever at the center of the neck (B). Surface roughness is quantified by AFM, and surface topology characterized in further detail (C).

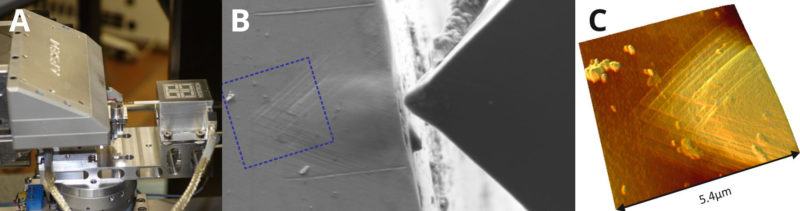

In the following application the AFSEM was used to study topological changes after a indentation.

AFSEM® and Hysitron PI85 SEM PicoIndenter® stage installed in a Zeiss Leo 982 SEM (A). The SEM is used to position the indenter tip and to measure the extent of topological changes after the indentation (B). The slip steps are quantified by AFM (C).

For more information, please visit the website from GETec Microscopy Website.